Control System Migration

Embarking on a control system upgrade can be a daunting task for many owner/operators. Collaborating with Focal Automation, however, not only enhances efficiency but can also prevent costly future repairs.

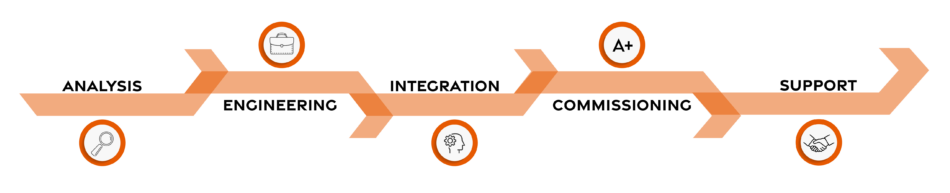

By identifying your technology challenges, our top-notch team of automation experts provides innovative solutions to address and resolve them. We offer online migrations to minimize downtime, as well as preplanned outage migrations during turnarounds, ensuring success through rigorous SAT/FAT testing.

Migration Strategy

Explore Our Solutions

Automation Services

We deliver unparalleled automation services across diverse industries including oil and gas, water and waste management, food and beverage, manufacturing, agriculture, and more. Whether launching new facilities or troubleshooting aging equipment, we are dedicated to delivering optimal solutions tailored to your specific needs.

Check out our Automation Solutions below to find out more!